EN 50575 Power, control and communication cables - Cables for general applications in construction works subject to reaction to fire requirements

1 Scope

This European Standard specifies reaction to fire performance requirements, test and assessment methods for electric cables used for the supply of electricity and for control and communication purposes, which are intended for use in construction works and subject to performance requirements on reaction to fire.

The cables covered by this standard are intended to be used for the supply of electricity and communications in buildings and other civil engineering works with the objective of limiting the generation and spread of fire and smoke.

Cables intended to be used for the supply of electricity, communication, and fire detection and alarm in buildings and other civil engineering works where it is essential to assure the continuity of power and/or signal supply of safety installations such as alarm, way guidance and fire fighting installations are not covered by this standard.

NOTE This European Standard does not replace the electrical, mechanical and environmental requirements that are essential to demonstrate compliance with other applicable cable standards/specifications

This European Standard covers:

-power cables-insulated conductors and cables for use in ,e.g.the supply of electricity;

-control and communication cables-wires, symmetric cables, and coaxial cables with metallic conductors for us in e.g. telecommunication, data transmission, radio frequency, video communication and signalling and control equipment;

-optical fiber cables- for use in ,e.g. telecommunication, data transmission, radio frequency, video communication and signalling and control equipment

3 Terms and definitions

For the purposes of this document the terms and the definitions given in EN13501_6, EN60754_2, EN 50399, EN60332-1-2, EN61034-2 and ENIS01716 and the following apply.

3.1 electric cable

all power, control and communication cables, including optical fiber cables and hybrid cables which are a combination of two or more of these cable types

3.2 power cable

assembly comprising one or more insulated conductor(s), together with any coverings and protective layers, used forthe transmission or supply of electrical energy

3.3 control cable

assembly comprising insulated conductors, together with any coverings and protective layers, used for the transmission of contro1, measuring and indication signals in electric installations

3.4 communication cable

assembly of suitably insulated coaxia1 conductors or twisted pairs of insulated conductors fabricated to meet transmission, mechanical and environmenta1 requirements, and sufficient to allow conveyance of information between two points with the minimum of radiation

3.5 optical fiber cable

assembly comprising one or more optical fibers or fiber bundles inside a common covering designed to protect them against mechanical stresses and other environmental influences while retaining the transmission quality of the fibers

3.6 product family

group of products produced by one manufacturer for which the test results for one or more characteristics from one product within the family are considered to be representative for that same characteristic for all other products within this family

4 Product characteristics

4.1 Reaction to fire

The contribution of power, control and communication cables to the development of fire shall be verified according to the test methods relevant for the claimed class as indicated in Clause5.

Test results shall be classified according to EN13501-6.

The contribution to the development of fire is classified regarding gross calorific potential, flame spread, total heat release, peak heat release rate and Fire Growth Rate Index(FIGRA) and is completed by additional classifications regarding smoke production, flaming droplets/particles and acidity.

4.2 Release of dangerous substances

National regulations on dangerous substances may require verification and declaration on release, and sometimes content, when products covered by this standard are placed on those markets. In the absence of European harmonized test methods,verification and declaration on release/content should be done taking into account national

provisions in the place of use.

NOTE An informative database covering European and national provisions on dangerous substances is available at the

Construction web site on EUROPA accessed through: http://ec.europa.eu/enterprise/construction/cpd-ds/

5 Test methods for reaction to fire classes

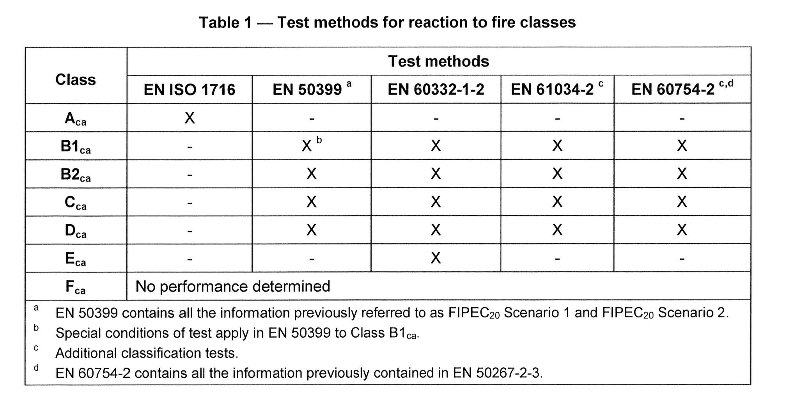

Table1 gives the reference to the European Standard containing the test methods to be used for the corresponding reaction to fire class.

Table1 -Test methods for reaction to fire classes

|

|

6 Assessment and verification of constancy of performance- AVCP

|

6.1 General

The compliance of power, control and communication cables with the requirements of this European Standard and with the performance (including classes) declared by the manufacturer in the Declaration of Performance(DoP) shall be demonstrated by:

- determination of the product-type,

- factory production control by the manufacturer, including product assessment.

The manufacturer shall always retain the overall control and sha1l have the necessary means to take responsibility for the conformity of the product with its declared performance.

6.2 Type testing

6.2.1 General

All performances related to characteristics included in this European Standard shall be determined when the manufacturer intends to declare the respective performances except where the standard gives provisions for declaring them without performing tests(e.g. use of previously existing data).

Where applicable the Extended Application(EXAP) rules given in CLC/TS50576 should be applied for the selection of suitable representative samples and applicability of test results to cables other than those tested.

Assessment previously performed in accordance with the provisions of this European Standard may be taken into account providing that they were made to the same test method, under the same AVCP system on the same product or products of similar design, construction and functionality such that the results are applicable to the product in question.

NOTE Same AVCP system means testing by, or testing witnessed or supervised by, an independent third party for products covered by system1+ and3, under the responsibility of a product certification body for products covered by system1+.

For the purpose of reaction to fire assessment; the manufacturer's products may be grouped into product families, where it is considered that the results for one or more characteristics from any one cable within the product family are representative for that same characteristic for all cables within that same product family.

In addition, the determination of product-type shall be performed for all characteristics included in the standard for which the manufacturer declares performances:

- at the beginning of the production of a new or modified power, control and communication cable

type(unless a member of the same product family); or

_ at the beginnir1g of a new or modified method of production(where this may affect the declared

performance); or

they shall be repeated for the appropriate characteristic(s), whenever a change occurs in the power, control and communication cable design, in the raw material or in the supplier of the components, or in the method of production(subject to the definition of a family), which would affect significantly one or more of the characteristics.

Products bearing regulatory marking in accordance with appropriate harmonized European specifications may be presumed to have the performances declared in the DoP, although this does not replace the responsibility on the power, control and communication cables manufacturer to ensure that the power, control and communication cables as a whole is correctly manufactured and have the declared performance values.

6.2.2 Test samples, testing and compliance criteria

For power, control and communication cables to be tested/assessed with regard to reaction to fire, as indicated in4.1, the test methods are given in Clause5 for the relevant claimed class and EN13501-6 gives the number of samples to be tested and the criteria for expressing the test results.

6.2.3 Test reports

The results of the determination of the product-type shall be documented in test reports. All test reports shall be retained by the manufacturer for atleast10 years after the last date of production of the power, control and communication cables to which they relate.

6.3 Factory production control (FPC)

6.3.1 General

The manufacturer shall establish, document and maintain an FPC system to ensure that the products placed on the market comply with the declared performance of the essential characteristics.

The FPC system shall consist of procedures, regular inspections, tests and/or assessments and the use of the results to control raw and other incoming materials or components, equipment, the production process and the product.

All the elements, requirements and provisions adopted by the manufacturer shall be documented in a systematic manner in the form of written policies and procedures.

This factory production control system documentation shall ensure a common understanding of the evaluation of the constancy of performance and enable the achievement of the required product performances and the effective operation of the production control system to be checked. Factory production control therefore brings together operational techniques and all measures al1owing maintenance and control of the compliance of the product with the declared performances of the essential characteristics.

6.3.2 Requirements

6.3.2.1 General

The manufacturer is responsible for organizing the effective implementation of the FPC system inline with the content of this product standard. Tasks and responsibilities in the production control organization shall be documented and this documentation shall be kept up-to-date.

The responsibility, authority and the relationship between personnel that manages, performs or verifies work affecting product constancy, shall be defined. This applies in particular to personnel that need to initiate actions preventing product non-constancies from occurring, actions in case of non- constancies and to identify and register product constancy problems.

Personnel performing work affecting the constancy of performance of the product shall be competent on the basis of appropriate education, training, skills and experience for which records shall be maintained.

In each factory, the manufacturer may delegate the action to a person having the necessary authority to:

- identify procedures to demonstrate constancy of performance of the product at appropriate stages; - identify and record any instance of non_constancy;

- identify procedures to correct instances of non-constancy.

The manufacturer shall draw up and keep up-to-date documents defining the factory production control. The manufacturer's documentation and procedures should be appropriate to the product and manufacturing process. The FPC system should achieve an appropriate level of confidence in the constancy of performance of the product. This involves:

a) the preparation of documented procedures and instructions relating to factory production control operations, in accordance with the requirements of the technical specification to which reference is made;

b) the effective implementation of these procedures and instructions;

c) the recording of these operations and their results;

d) the use of these results to correct any deviations, repair the effects of such deviations, treat any resulting instances of non-conformity and, if necessary, revise the FPC to rectify the cause of non-constancy of performance.

Where subcontracting takes place, the manufacturer shall retain the overall control of the product and ensure that he receives all the information that is necessary to fulfill his responsibilities according to this European Standard.

If the manufacturer has part of the product designed, manufactured, assembled, packed, processed and/or labeled by subcontracting, the FPC of the subcontractor may be taken into account, where appropriate for the product in question.

A manufacturer who subcontracts all of his activities may in no circumstances pass these responsibilities on to a subcontractor.

NOTE Manufacturers having an FPC system which complies with ENIS09001 standard and which addresses the requirements of this European Standard are considered as satisfying the FPC requirements of the Regulation (EU) No305/2011.

6.3.2.2 Equipment

6.3.2.2.1 Testing

All weighing, measuring and testing equipment shall be calibrated and regularly inspected according to documented procedures, frequencies and criteria.

6.3.2.2.2 Manufacturing

All equipment used in the manufacturing process shall be regularly inspected and maintained to ensure use, wear or failure does not cause inconsistency in the manufacturing process. Inspections and maintenance shall be carried out and recorded in accordance with the manufacturer's written procedures and the records retained for the period defined in the manufacturer's FPC procedures.

6.3.2.3 Raw materials and components

The specifications of all incoming raw materials and components shall be documented, as shall the inspection scheme for ensuring their compliance.

6.3.2.4 Trace-ability and marking

Individual cable batches shall be identifiable and traceable with regard to their production origin. The manufacturer shall have written procedures ensuring that processes related to affixing trace-ability codes and/or markings are inspected regularly.

6.3.2.5 Controls during manufacturing process

The manufacturer shall plan and carry out production under controlled conditions, appropriate to the particular manufacturing process.

6.3.2.6 Product testing and evaluation

The manufacturer shall establish procedures to ensure that the stated values of the characteristics that he declares are maintained. The characteristics, and the means of control, are:

- reaction to fire characteristics shall be subject to the tests indicated in Clause5 at least once per year. Only one product sample shall be selected from each product family.

The test frequency may be reduced subject to the provisions of 6.3.3.

6.3.2.7 Non-complying products

The manufacturer shall have written procedures which specify how non-complying products shall be dealt with. Any such events shall be recorded as they occur and these records shall be kept for the period defined in the manufacturer's written procedures.

Where the product fails to satisfy the acceptance criteria, the provisions for non-complying products shall apply, the necessary corrective action shall immediately be taken and the products or batches not complying shall be isolated and properly identified.

Once the fault has been corrected, the test or verification in question shall be repeated.

The results of controls and tests shall be properly recorded. The product description, date of manufacture, test method adopted, test results and acceptance criteria shall be entered in the records under the signature of the person responsible for the control/test.

With regard to any control result not meeting the requirements of this European Standard, the corrective measures taken to rectify the situation(e.g. further test carried out, modification of manufacturing process, scrapping or correction of product) shall be indicated in the records.

6.3.2.8 Corrective action

The manufacturer shall have documented procedures that instigate action to eliminate the cause of non-conformities in order to prevent recurrence.

6.3.2.9 Handling, storage and packaging

The manufacturer shall have procedures providing methods of product handling and shall provide suitable storage areas preventing damage or deterioration.

6.3.3 Product specific requirements

The FPC system shall address this European Standard, and ensure that the products placed on the market comply with the declaration of performance.

The FPC system sha1l include a product specific FPC, which identifies procedures to demonstrate compliance of the product at appropriate stages, i.e.:

a) the controls and tests to be carried out prior to and/or during manufacture according to a frequency laid down in the FPC test plan, and/or

b) the verification's and tests to be carried out on finished products according to a frequency laid

down in the FPC test plan.

If the manufacturer uses only finished products, the operations under b) shall lead to an equivalent level of compliance of the product as if FPC had been carried out during the production.

If the manufacturer carries out parts of the production himself, the operations under b) may be reduced and partly replaced by the operations under a). Generally, the more parts of the production that are carried out by the manufacturer, the more operations under b) may be replaced by operations under a).

In any case the operation shall lead to an equivalent level of compliance of the product as if FPC had been carried out during the production.

NOTE Depending on the specific case, it can be necessary to carry out the operations referred to under a) and b), only the operations under a) or only those under b).

The operations under a) refer to the intermediate states of the product as on manufacturing machines and their adjustment, and measuring equipment, etc. These controls and tests and their frequency shall be chosen based on product type and composition, the manufacturing process and its complexity, the sensitivity of product features to variations in manufacturing parameters, etc.

The manufacturer sha1l establish and maintain records that provide evidence that the production has been sampled and tested. These records shall show clearly whether the production has satisfied the defined acceptance criteria and shall be available for at least three years.

6.3.4 Initial inspection of factory and FPC

Initial inspection of the factory and of FPC for products covered by AVCP system1+ shall be carried out when the production process has been finalized and in operation. The factory and FPC documentation shall be assessed to verify that the requirements of 6.3.2 and6.3.3 are fulfilled.

During the inspection, it shall be verified:

a) that all resources necessary for the achievement of the product characteristics required by this

European Standard are in place and correctly implemented, and

b) that the FPC-procedures in accordance with the FPC documentation are followed in practice, and c) that the product complies with the product-type samples, for which compliance of the product performance to the DoP has been verified.

All locations where final manufacture and final testing of the relevant product is performed shall be assessed to verify that the above conditions a) to c) are in place and implemented. If the FPC system covers more than one product, production line or production process, and it is verified that the general requirements are fulfilled when assessing one product, production line or production process, then the assessment of the general requirements does not need to be repeated when assessing the FPC for another product, production line or production process.

All assessments and their results sha1l be documented in the initial inspection report.

6.3.5 Continuous surveillance of FPC(for products covered by AVCP system1+)

Surveillance of the FPC shall be undertaken twice per year.The surveillance of the FPC shall include a review of the FPC test plan(s) and production process(es) for each product to determine if any changes have been made since the last assessment or surveillance. The significance of any changes shall be assessed.

Checks shall be made to ensure that the test plans are still correctly implemented and that the production equipment is still correctly maintained and calibrated at appropriate time intervals.

Audit testing for reaction to fire characteristics shall be carried out once every3 years on product samples selected from the production of products for which the manufacturer makes a declaration of performance(DoP).

Only one product sample shall be selected from each product family.

The repeat audit testing interval for a product type may be extended to once every 5 years providing that two consecutive audits have been satisfactorily completed.

Reaction to fire characteristics shall be subject to the tests indicated in Clause5.

Samples shall be selected from finished goods which have been released for sale by the manufacturer.

The records of tests and measurements made during the production process and on finished products shall be reviewed to ensure that the values obtained still correspond with those values for the samples submitted to the determination of the product-type and that the correct actions have been taken for non-compliant products.

6.3.6 Procedure for modifications

If modifications are made to the product, production process or FPC system that could affect any of the product characteristics declared according to this European Standard, then all characteristics for which the manufacturer declares performance, which may be affected by the modification, shall be subject to the determination of product-type as described in6.2.1.

where relevant, a re_assessment of the factory and of the FPC system shall be performed for those aspects, which may be affected by the modification.

All assessments and their results shall be documented in a report.

6.3.7 One-off products, pre-production products(e.g. prototypes)and products produced in

very low quantities power, control and communication cables produced as a one-off, prototypes assessed before full production is established and products produced in very low quantities-less than10 km in length and less than5 t in weight per year- shall be assessed as follows:

For type assessment, the provisions of 6.2.1 paragraph3 apply; together with the following additional provisions:

_ in the case of prototypes, the test samples sha1l be representative of the intended future

production and shall be selected by the manufacturer;

_ on request of the manufacturer, the results of the type assessment of prototype samples may be

included in a certificate or in test reports issued by the involved third party.

The FPC system of one-off products and products produced in very low quantities shall ensure that raw materials and/or components are sufficient for production of the product. The provisions on raw materials and/or components shall apply only where appropriate. The manufacturer shall maintain records allowing trace-ability of the product.

For prototypes, where the intention is to move to series production, the initial inspection of the factory and FPC shall be carried out before the production is already running and/or before the FPC is already in practice. The following shall be assessed:

- the FPC-documentation, and

- the factory.

In the initial assessment of the factory and FPC, it shall be verified:

a) that all resources necessary for the achievement of the product characteristics included in this

European Standard will be available, and

b) that the FPC procedures in accordance with the FPC documentation will be implemented and

fo1lowed in practice, and

c) that procedures are in place to demonstrate that the factory production processes can produce a product complying with the requirements of this European Standard and that the product will be

the same as the samples used for the determination of the product-type, for which compliance with

this European Standard has been verified.

Once series production is fully established, the provisions of 6.3 shall apply.

7 Marking, label-ling and packaging

7.1 Marking

Power, control and communication cables sha1l be marked with:

a) an indication of origin consisting of the marking of the manufacturer's name or trademark, or(if legally protected) identification number;

b) the product description or code designation;

c) the reaction to fire class.

The marking may be on the cable or on its packaging or on its label-ling or any combination of the preceding.

In addition, power, control and communication cables may also be marked with the following elements:

d) any information required by other standards relevant to the product;

e) the year of production;

f) voluntary certification marks;

g) any additional information as wished by the manufacturer provided that it does not conflict with,,nor confuse any of the other required marking.

The marking may be on the cable or on its packaging or on its label-ling or any combination of the preceding.

Where regulatory marking provisions require information on some or all items listed in this clause, the requirements of this clause concerning those common items are deemed to be met.

7.2 Form of marked elements

When applied on the electric cable, the elements given in7.1 a), 7.1 b) and7.1 c) shall be applied by printing, indenting or embossing on the sheath or in the case of unsheathed cables on the insulation. The marking shall be continuous. Each specified marking shall be regarded as continuous if the distance between the end of the marking and the beginning of the next identical marking does not exceed1 100 mm.

7.3 Legibility of marking

All marking shall be legible. Printed marking shall be non-degradable